Contrary to certain industry trends, we focus on regular investments in our technology park, and on sourcing the most advanced equipment that meets the requirements of our printing projects.

Printing 288 000 000 pages per hour

The Heidelberg XL 106 is at its peak of performance when it prints more than 18,000 sheets per hour, or the equivalent of 288,000 pages.

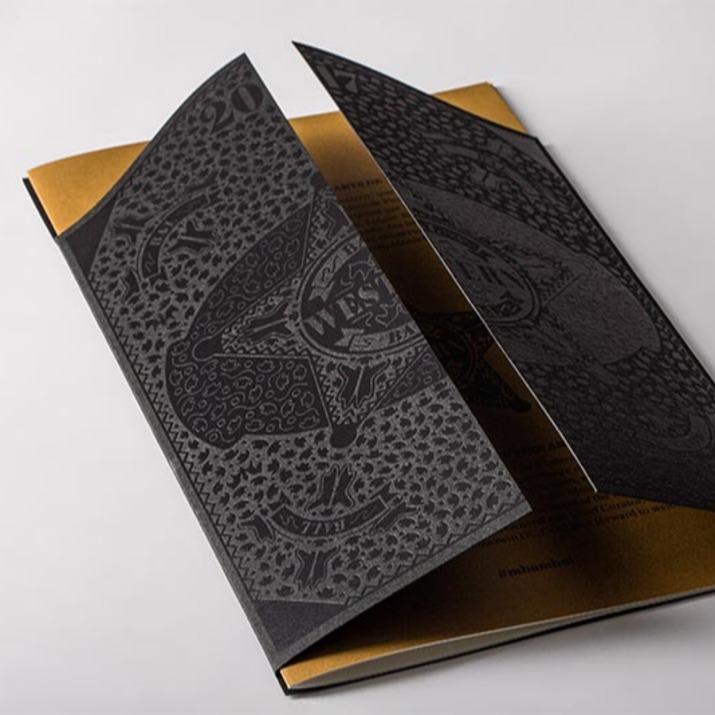

For its 57th Annual Ball, the Montreal Museum of Fine Arts chose a Western theme, an emblematic universe that needed to be revisited. With its SuedeTex paper, satin black stamping and light embossing, this invitation recreated the atmosphere of a saloon with its refined textures and metallic inks.

For its 57th Annual Ball, the Montreal Museum of Fine Arts chose a Western theme, an emblematic universe that needed to be revisited. With its SuedeTex paper, satin black stamping and light embossing, this invitation recreated the atmosphere of a saloon with its refined textures and metallic inks.

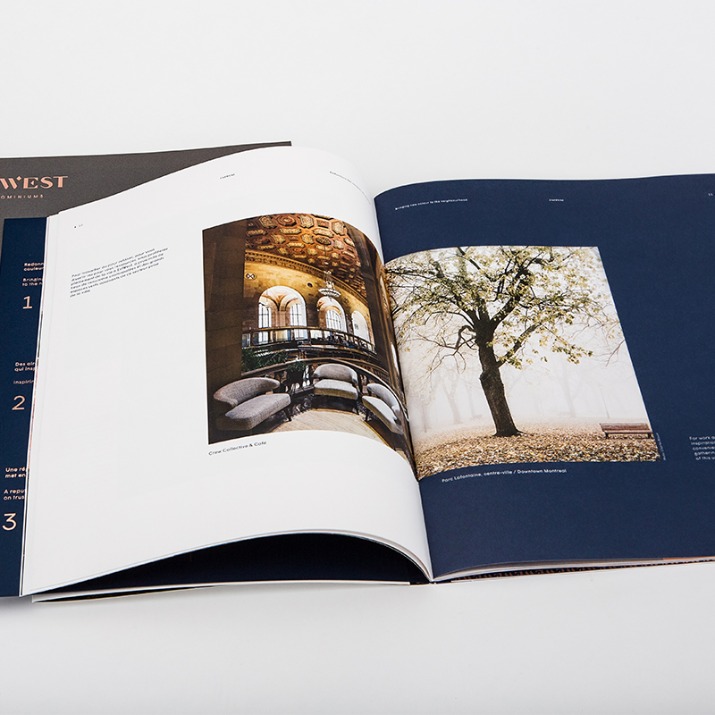

This project involved producing a booklet of cardboard paper samples used to demonstrate the printing and converting flexibility of Kallima cardboards.

In this booklet, printing prowess meets precision embossing on multiple levels. The addition of a gold glitter varnish adds a festive note. The varnishes highlight the embossed elements while respecting the customer's environmental values.

This project involved producing a booklet of cardboard paper samples used to demonstrate the printing and converting flexibility of Kallima cardboards.

In this booklet, printing prowess meets precision embossing on multiple levels. The addition of a gold glitter varnish adds a festive note. The varnishes highlight the embossed elements while respecting the customer's environmental values.

Index Design is a reference for the Quebec interior design industry. L'Empreinte has been printing this long-awaited trend magazine for architects, interior designers and manufacturers for the past 12 years. In this sector sensitive to environmental responsibility, l'Empreinte has made a shift and started using UV printing solutions without VOCs (volatile organic compounds) while not compromising on print quality.

Index Design is a reference for the Quebec interior design industry. L'Empreinte has been printing this long-awaited trend magazine for architects, interior designers and manufacturers for the past 12 years. In this sector sensitive to environmental responsibility, l'Empreinte has made a shift and started using UV printing solutions without VOCs (volatile organic compounds) while not compromising on print quality.

Infopresse publishes this annual guide once a year in collaboration with the Association of creative communication agencies. This essential tool for the communications industry uses a UV technology which has enabled l'Empreinte to maintain the highest quality by using substrates that are renowned for their environmentally friendly properties.

Infopresse publishes this annual guide once a year in collaboration with the Association of creative communication agencies. This essential tool for the communications industry uses a UV technology which has enabled l'Empreinte to maintain the highest quality by using substrates that are renowned for their environmentally friendly properties.

Adapted to today's pace, our digital services take advantage of the very latest technologies in digital printing. This type of printing is ideal for smaller runs or where speed is required.

Combined with our variable data custom printing services, this service allows you to manage highly personalized campaigns and to produce high-quality materials. We have one of the most powerful digital presses on the market, giving your products an exceptional level of quality with second-to-none reliability.

Is it or isn’t it digital? Hard to say at a glance!